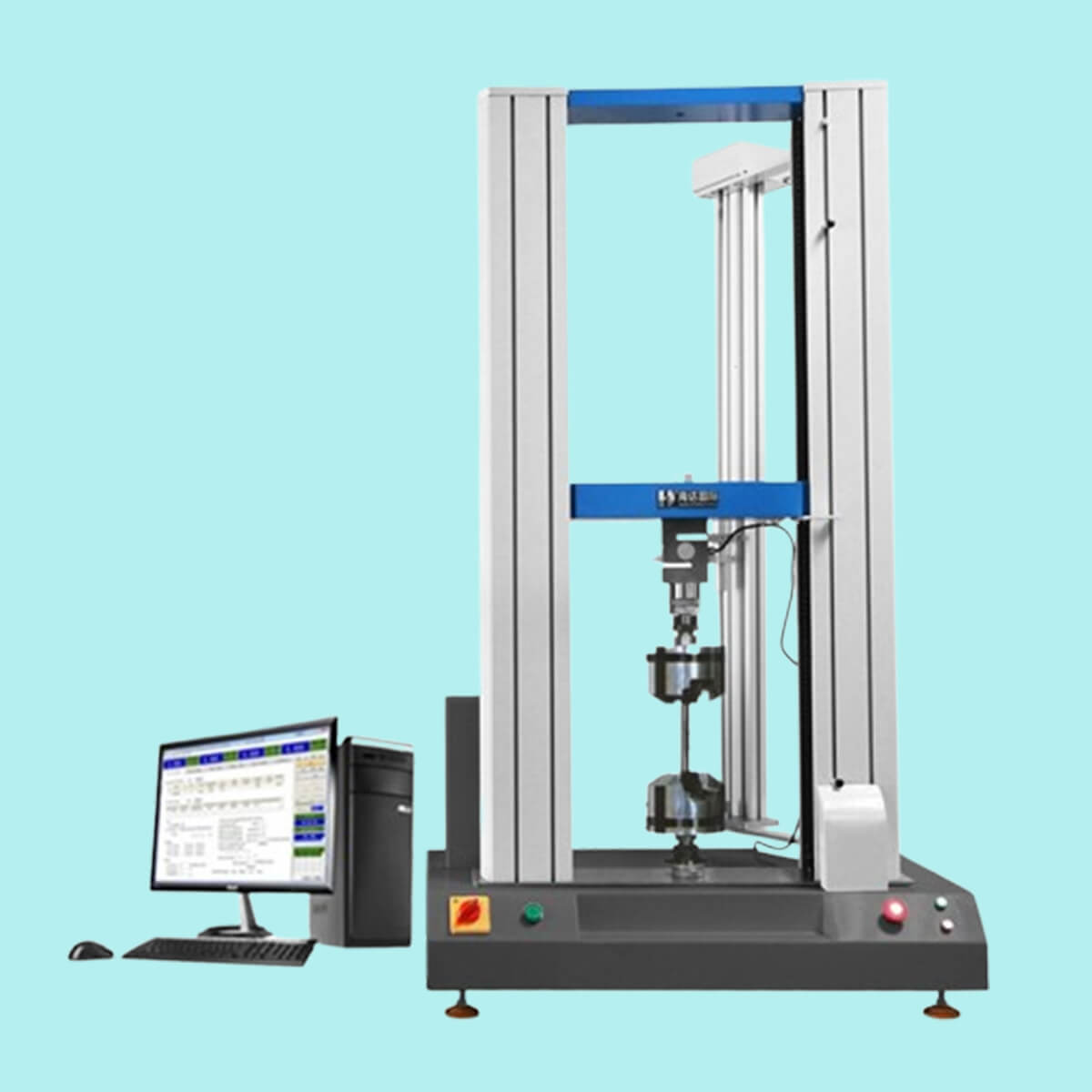

Mechanical Testing Services

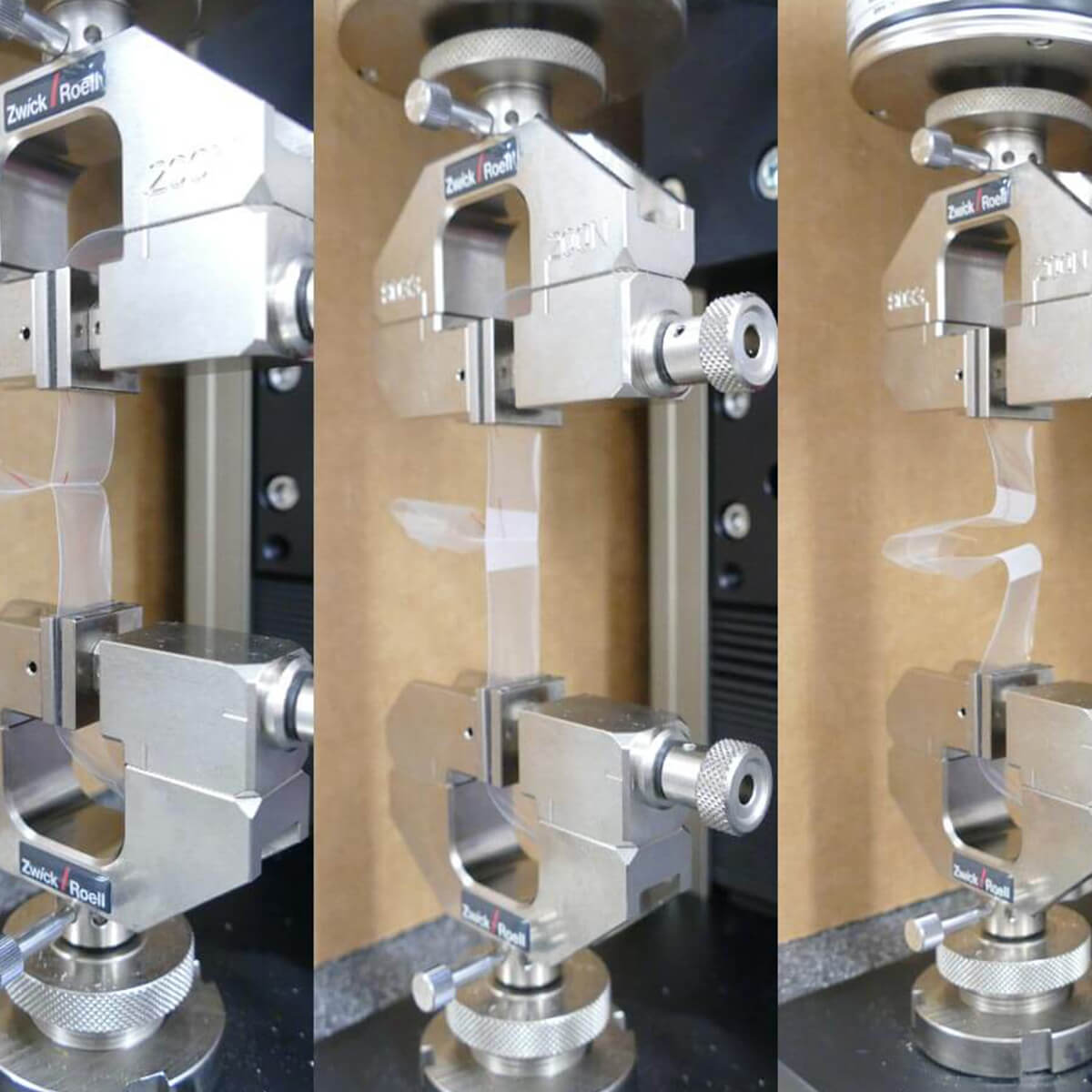

Mechanical Testing plays a crucial role in understanding the behaviour and properties of materials under various conditions. These tests provide essential data for manufacturers, engineers and researchers to assess the suitability, reliability, and performance of materials in different applications.

The Mechanical testing laboratory having a state of the art laboratory facilities with highly sophisticated instruments to meet the expectation of the manufacturing industry.

Our testing capability products in mechanical (physical dimension & performance testing) as per IS/ISO/ASTM/EN/USP/EP/IP/Customer Supplied Test Method:

- Blood Bags

- Catheters

- Condoms (Male & Female)

- Copper T

- Tubal Rings

- Hypodermic Syringes, Hypodermic Needles

- Disposable Syringes, Disposable Needles

- Insulin Syringes

- Surgical & Examination Gloves

- Rubber Products

- Urological Bag. Bag, Urological Device and Accessories

- Sanitary Napkin

- Disposable Infusion/Perfusion

- Cannula

- Microsurgical Blade

- Wound Dressing

- Surgical/Sterile Garments

- Intraocular Lens

- Capsular Tension Ring

- Injector Cartridge

- Surgical Instruments

- Blood Collection Tubes